Pneumatic Elevators vs. Machine Room-Less (MRL) Elevators: Which is Right for You?

Pneumatic elevators and machine room-less (MRL) elevators stand out as two of the most cutting-edge and effective technologies in the search for vertical mobility solutions. Both have fundamentally changed how we think about and use elevators in contemporary structures, from single-family homes to office towers.

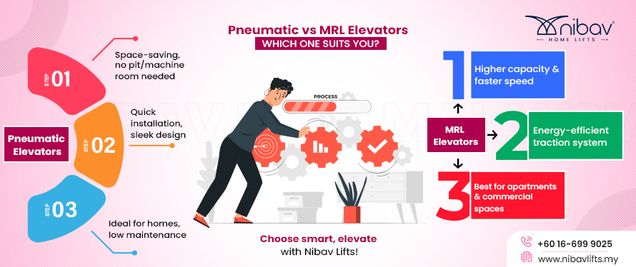

This paper explores the features, benefits, and application scenarios of MRL versus pneumatic elevators and offers a straightforward comparison to assist you in making an informed choice.

Overview of Technologies for Elevators

Today’s architectural designs are incomplete without elevators since they solve the problem of vertical movement in multi-story buildings. Pneumatic elevators and MRL elevators are two innovations in elevator technology that have their advantages and are best suited for particular uses.

Knowledge about Pneumatic Elevators

Vacuum pressure is the basis for how pneumatic elevators transfer the elevator car between levels. This technique gives off a futuristic appearance by using a tube-shaped cabin enclosed in a clear polycarbonate shaft. The elevator car can climb because of the vacuum above it, and it may descend more easily because of the carefully timed release of air pressure.

Benefits

- Space Efficiency: They are perfect for houses or buildings with limited space because of their small form, which eliminates the need for a pit or machine room.

- Installation Ease: Without requiring significant alterations, they are readily adapted into pre-existing structures.

- Aesthetic Appeal: The 360-degree views provided by the clear shaft improve any space’s interior décor.

Find out more about the benefits of pneumatic house lifts.

Drawbacks:

- Limited Capacity: In comparison to conventional elevators, it usually supports fewer passengers and less weight.

- Slower Speeds: Because they move more slowly, they are less appropriate for busy business environments.

Investigating MRL (machine room-less) elevators

As the name implies, machine room-less (MRL) elevators do not need a separate machine room. The traction drive technology in MRL elevators uses ropes and a counterweight for movement, which is more energy-efficient and provides a smoother ride. The motor is compactly integrated into the elevator shaft, saving important building space.

Benefits

- Space and Cost Savings: Removes the requirement for a machine room, which lowers building expenses and releases restrictions on architectural design.

- Greater Capacity and Speed: Compared to pneumatic elevators, they can move faster and accommodate more passengers, which makes them perfect for high-rise residential and commercial buildings.

- Energy Efficiency: With regenerative drives that allow energy to be fed back into the building’s power supply, it uses less energy than hydraulic elevators.

Drawbacks:

- Complex Installation: necessitates more involved installation procedures and may call for alterations to the building’s structural design.

- Maintenance: Although there are fewer mechanical parts, the shaft itself needs to be maintained, which can be more difficult.

An analysis of pneumatic and MRL elevators side by side

For a better understanding of the differences between MRL and pneumatic elevators, consider the following brief comparison:

| Feature | Pneumatic Elevators (PE) | Machine Room-Less Elevators (MRL) |

| Installation | Faster and less invasive, may be put in existing structures. | More complex, frequently included in new buildings or large renovations. |

| Space | Requires extremely minimal area; no pit or machine room is needed. | Efficient utilization of space within the shaft; no separate machine room needed. |

| Availability | Easy access for dwellings, limited by the weight and size capacity. | High accessibility, suited for frequent use in different building types. |

| Beauty | Sleek, modern design that can function as a visual centerpiece | Customizable to building aesthetics and less visually invasive |

| Maintenance | Lower maintenance because there are fewer moving parts. | Regular maintenance is needed, however there is no machine room upkeep. |

| Safety of Features | unexpected descent and systems for braking | Extensive safety measures, including lighting for emergencies, alarms, and communication systems. |

| Sounds | Very quiet operation | Quiet operation; noise primarily from the movement of the cab. |

| Quickness | Slower than MRL and regular elevators. | Faster, appropriate for buildings with numerous storeys. |

| Sturdiness | High durability, with fewer mechanical components. | Very durable and suitable for intensive use in commercial environments. |

| Customization | Due to design constraints, modification choices are limited. | Finishes, sizes, and features are highly customizable. |

| Disability-Related Issues | The limited space may not allow all sorts of wheelchairs. | Typically constructed to conform to ADA rules, accommodating wheelchairs and other aids. |

| Wheelchair For Accessibility | Due to size, it may not be possible to fit all types of wheelchairs. | Designed to be wheelchair accessible and satisfy ADA criteria |

| Impact on the Environment | Minimal, with air as the primary operating mechanism. | Low, particularly versions with regenerative motors that reduce power usage. |

| Easy Travel | Provides a smooth ride yet may be significantly slower. | Known for smooth and rapid functioning. |

| Principle of Operation | Uses vacuum pressure to lift the elevator cab. | Using a traction system eliminates the requirement for a separate machine room |

| Efficiency in Space | Highly space-efficient, with a minimum footprint. | More space-efficient than standard elevators, but requires room for components in the shaft. |

| Energy Efficiency | High, with low energy spent during descent. | Higher, frequently fitted with energy recovery equipment. |

| Capacity for Weight | Lower, ideal for domestic use. | Higher, intended for both home and business use. |

| Construction Codes | Vacuum elevators must meet strict building requirements. | Commercial elevator systems must comply with severe building codes. |

| Construction | Minimal building is required and can be retrofitted in existing homes. | Needs structural considerations for the shaft and components. |

| Safety Points to Remember | Includes safety features for power outages and emergency descents. | Comprehensive safety measures include emergency brakes and backup power. |

| Exemptions for Construction | There may be exemptions due to less invasive installation. | Generally, no exclusions; must comply with all applicable construction rules. |

| Friendly to Seniors | Seniors will find it user-friendly and safe, but its size may be an issue for others. | Equipped with characteristics that make it safe and accessible to the elderly |

| Cost | Ranges from RM 1,39,000 to RM 259,000 | Ranges from RM 1,39,000 to RM 279,000 |

Find out more about the costs that influence the cost of a house elevator!

Utilization and Appropriateness

The ideal uses for pneumatic elevators are in residential settings, especially in residences with limited space or where constructing a standard elevator is impractical because of structural constraints. They provide a great way to improve mobility without sacrificing the beauty of the design.

In contrast, MRL elevators are the preferred option for high-rise residential developments and commercial structures. Their velocity and capacity make them suitable for situations where there is a lot of traffic, offering dependable and effective vertical transit.

The application environment, available space, and particular mobility requirements are some of the criteria that influence the decision between a pneumatic and an MRL elevator. While MRL elevators meet the demanding needs of commercial and high-rise residential structures, pneumatic elevators provide a balance of elegance and performance for individual residences. Whichever option is selected, these technologies represent a significant advancement in improving the usability and accessibility of our facilities.

In conclusion, it appears that vertical mobility will continue to grow, with MRL and pneumatic elevators setting the pace. We may anticipate even more creative ideas to arise as technology develops, drastically altering the field of modern architecture.

FAQ’s

1. What is the key difference between pneumatic and MRL elevators?

Pneumatic elevators use air pressure for smooth, energy-efficient travel, while MRL elevators rely on traction systems. Nibav Home Lifts Malaysia offers compact, space-saving pneumatic lifts perfect for homes without major structural changes.

2. Which elevator type is easier to install in homes?

Pneumatic elevators require minimal construction and fit into small spaces, making them ideal for home upgrades. Nibav lifts offer plug-and-play installation, unlike MRL elevators that need dedicated machine rooms and complex structural modifications.

3. Are pneumatic elevators energy-efficient?

Yes, pneumatic lifts consume less power by using air pressure for movement, reducing electricity costs. Nibav Home Lifts Malaysia provides eco-friendly solutions with low maintenance, unlike MRL elevators, which require more energy and upkeep.

4. Which elevator offers better safety and reliability?

Pneumatic lifts feature an airtight cabin with automatic brakes and emergency lowering. Nibav lifts prioritize safety with backup power and high durability, whereas MRL elevators rely on mechanical traction systems that need frequent maintenance.

5. What is the best home elevator choice for seniors?

Pneumatic elevators offer seamless, step-free access, making them perfect for seniors and mobility-challenged users. Nibav Home Lifts Malaysia provides smooth, quiet, and easy-to-use solutions, unlike MRL elevators that require pits and complex installation.